カテゴリー

- Instruments | Valve | Union Bonnet Valves

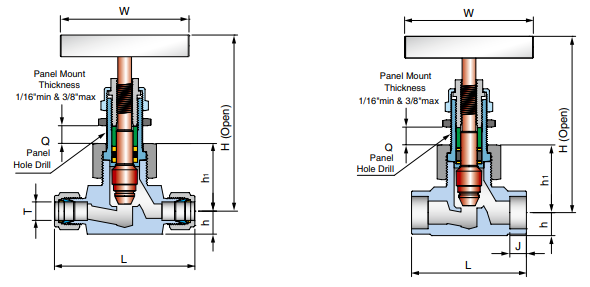

- Dimensions

- How To Order

- Pressure-Temperature Ratings

- Features

Dimensions

| Part No. | End Connections | Orifice | CV | Dimensions (mm) | |||||||||

| Inlet | Outlet | L | L1 | h | h1 | H (open) | W | Q | J | ||||

| VU61 | U-04T- | 1/4" UNILOK | 4.0 | 0.35 | 61.9 | 31 | 9.6 | 27.8 | 77.8 | 45.0 | 15.1 | - | |

| U-M06T- | 6mm UNILOK | ||||||||||||

| U-M08T- | 8mm UNILOK | ||||||||||||

| WS-04T | 1/4" Tube SW | 46 | 23 | 7.2 | |||||||||

| VU62 | U-06T- | 3/8" UNILOK | 6.4 | 0.86 | 72 | 36 | 12.7 | 34.1 | 93.7 | 64.0 | 19.9 | - | |

| U-08T- | 1/2" UNILOK | 77.8 | 38.9 | ||||||||||

| U-M10T- | 10mm UNILOK | 73 | 33.3 | ||||||||||

| U-M12T- | 12mm UNILOK | 78 | 39 | ||||||||||

| WS-06T | 3/8" Tube SW | 57.2 | 25.4 | 8.0 | |||||||||

| WS-08T | 1/2" Tube SW | 57.2 | 25.4 | 9.6 | |||||||||

| WS-04P | 1/4" Pipe SW | 57.2 | 28.6 | ||||||||||

| VU63 | U-08T- | 1/2" UNILOK | 9 | 2.20 | 97 | 48.5 | 15.9 | 46.0 | 121.5 | 89.0 | 26.2 | - | |

| U-12T- | 3/4" UNILOK | ||||||||||||

| U-16T- | 1" UNILOK | 11 | 100 | - | 17.5 | 47.6 | |||||||

| U-M12T- | 12mm UNILOK | 98 | 43.7 | 15.9 | 46.0 | ||||||||

| WS-08T | 1/2" Tube SW | 10 | 79.4 | 39.7 | 9.6 | ||||||||

| WS-12T | 3/4" Tube SW | 79.4 | - | 11.1 | |||||||||

| WS-08P | 1/2" Pipe SW | 11 | 79.4 | 39.7 | 9.6 | ||||||||

How To Order

UNILOK VU6 series union bonnet valves are ordered by part number as shown below.

Example: The following part number, VU62F-04N-SS is designated for VU6 series union bonnet valve with1/4" female NPT to 1/4" female NPT, 316SS.

| V | U62 | F | - | 04N | - | SS | - | - | ||

| UNILOK Valve | Valve Type | Connection type | Connection Size | Body Materials | Stem Type | Packing Materials | ||||

| Valve Type | Connection Size | Body Materials | |||||||||||||||

| U6 | Straight Pattern | Fractional(Inch) Tube O.D. Designation | SS | 316SS | |||||||||||||

| U6A | Angle Pattern | Tube O.D. | inch | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | MO | Alloy 400 | ||||||

| mm | 3.17 | 6.35 | 9.52 | 12.70 | 19.05 | 25.40 | Other alloys are available upon request | ||||||||||

| Connection Type | Designator | 02T | 04T | 06T | 08T | 12T | 16T | ||||||||||

| U | UNILOK Tube Fitting | Stem Type | |||||||||||||||

| F | Female NPT or ISO7/1(PT) | Metric Tube O.D. Designation | None | Vee Stem | |||||||||||||

| M | Male NPT or ISO7/1(PT) | Tube O.D. | mm | 6 | 8 | 10 | 12 | R | Regulating | ||||||||

| WS- | Socket Weld -Tube | Designator | M06T | M08T | M10T | M12T | S | Soft-seat | |||||||||

| WS- | Socket Weld - Pipe | B | Ball | ||||||||||||||

| Pipe Size Designation (NPT or ISO7/1-PT) | |||||||||||||||||

| Pipe Size | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | Packing Materials | ||||||||||

| Designator | 02N/R | 04N/R | 06N/R | 08N/R | 12N/R | 16N/R | None | PTFE | |||||||||

| PK | PEEK | ||||||||||||||||

| Weld Size Designation | GF | Grafoil | |||||||||||||||

| Tube Size | 1/4 | 3/8 | 1/2 | 3/4 | |||||||||||||

| Designator | 04T | 06T | 08T | 12T | |||||||||||||

| Pipe Size | 1/4 | 3/8 | 1/2 | ||||||||||||||

| Designator | 04P | 06P | 08P | ||||||||||||||

Pressure-Temperature Ratings

| Body Material | Stem | PTFE packing | Packing Material | Body Material | Temperature

Rating | Pressure Rating @ Max. Temperature | ||||||

| Temperature Rating | Pressure Rating @ 38℃ | |||||||||||

| ℃ | ℉ | psig | bar | |||||||||

| ℃ | ℃ | psig | bar | PTFE | 316SS | -54~232 | -65~450 | 4130 | 285 | |||

| 316SS | Vee, Ball, Regulating | -54~232 | -65~450 | 6000 | 413 | Alloy 400 | 3970 | 274 | ||||

| Soft-seat (Kel-F) | -54~93 | -65~200 | PEEK | 316SS | -54~315 | -65~600 | 3760 | 260 | ||||

| Alloy 400 | Vee, Ball, Regulating | -54~232 | -65~450 | 5000 | 345 | Alloy 400 | -54~260 | -65~500 | 3960 | 273 | ||

| Soft-seat (Kel-F) | -54~93 | -65~200 | Grafoil | 316SS | -54~648 | -65~1200 | 1715 | 119 | ||||

| For the service with aromatic heat transfer fluids or concentrated sulfuric and nitric acids, PEEK is not recommended. | Alloy 400 | -54~260 | -65~500 | 3960 | 273 | |||||||

| Alloy 400/Monle is not applicable over 260℃(500℉) | ||||||||||||

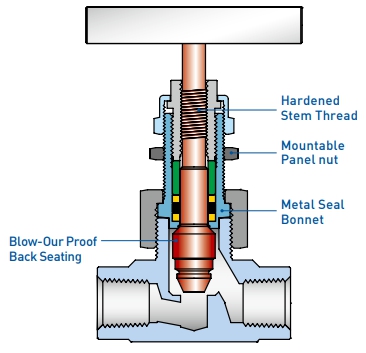

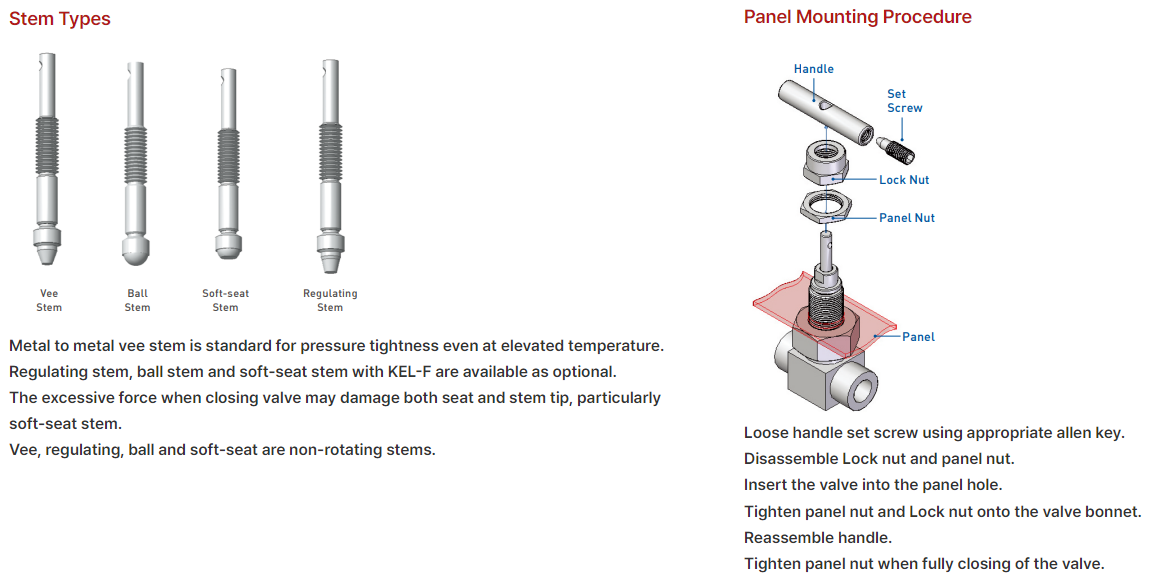

Features

Pressure rating up to 6000 psig (413 bar) @38°C (100°F).

Temperature rating from -53°C (-65°F) to 232°C (450°F) with standard PTFE packing, up to 648°C (1200°F) with Grafoil packing.

Roll-threaded and hardened stem for long cycle life.

Union bonnet design to ensure a high-integrity seal under severe environments.

Panel mounting without packing disruption.

top

top