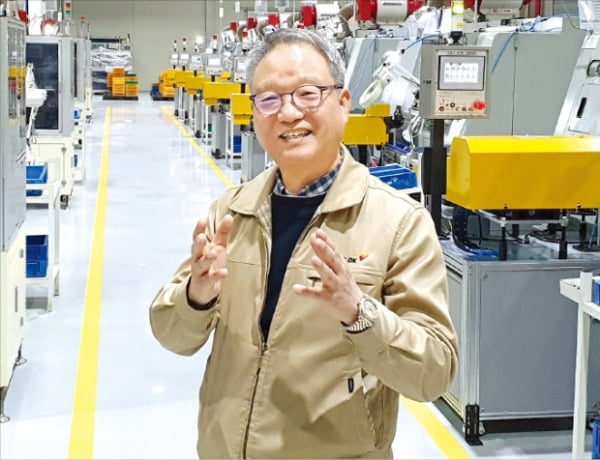

Yoo Myung-ho, Unilok CEO, “Supply high-performance valves to Samsung E…

최고관리자

2020-04-02

“R&D will continue even in times of crisis… We will open an era of 100 billion won in sales.”

As the economic downturn and the novel coronavirus infection (COVID-19) situation prolong, difficulties for companies are increasing. However, amidst this, there are companies located in industrial complexes that are preparing for the future through bold facility investment and management innovation. Unilok, which produces high-performance valves, invested 48 billion won and recently completed a new factory in Sihwa MTV and prepared for a leap forward. We also set a vision to reach 100 billion won in sales within a few years.

Pipes pass through the production lines of major factories, including semiconductor factories. This is a pipe that transports fluids, gases, etc. There are valves throughout the pipes. Although it is a small part, it plays a very important role. If the fluid or gas flowing inside is an explosive chemical or harmful gas, it may lead to an accident if it is not properly controlled.

Unilok (CEO Yoo Myung-ho, 63), located in Sihwa MTV (Multi-Techno Valley), is a company that manufactures high-performance valves used in such areas. Many of these valves have been domestically produced one by one, although American or Japanese companies have dominated the domestic market. An ultra-small fluid transportation system was also developed. It is a precision product mainly supplied by Japanese companies. We also domestically produced a high-performance regulator for semiconductors that prevents gas leaks due to corrosion by applying proprietary metal coating technology.

Now, products that surpass the technology of advanced countries have begun to be introduced. The newly developed process valve has a response speed of less than 5/1000 seconds. You can control it in a short amount of time. This means that fluid can be controlled in precise amounts. CEO Yoo explained, “The valve has moved beyond its simple opening and closing function and has become a key component that determines the success or failure of the manufacturing process.”

The company completed construction of a new factory here at the end of last year. It has a land area of approximately 20,000 m2 and a total floor area of 15,000 m2. A factory, office building, and welfare building were built. A site of 7,600 m2 was reserved for expansion. The total investment cost was 48 billion won (based on completion of facility investment), including land purchase, construction, and facility investment. When you enter the third floor of the office building, Sihwa Lake unfolds before your eyes. Across the street, you can see a wide field including the Hwaseong Dinosaur Egg Fossil Site at a glance. The late afternoon sunset is spectacular.

The reason it was located here is because the Korea Industrial Complex Corporation, which sold Sihwa MTV, classified the company's industry as a high-tech industry. Every corner of the factory is a clean space. CEO Yoo said, “Because this product is supplied to a semiconductor factory, the clean room level of our factory is similar to that of a semiconductor factory.” Main domestic customers include Samsung Electronics and SK Hynix. It is exported to over 40 countries in the United States, Europe, Asia, the Middle East, and South America. Transaction partners include companies in the petrochemical, power and energy, semiconductor, bio, and fuel cell fields. We supply it under our own brand, ‘Uni-Lok’.

The company's growth stems from CEO Yoo's obsession with technology development. After graduating from school, he joined a fittings and valves production company in Cheonggyecheon, Seoul and took charge of sales. In this process, he learned product characteristics and later reached a level where he could develop technology. The company was founded in 1984 near Anyangcheon Stream near the Guro Tool Shopping Center in Seoul with one technician and one female employee. We did not let up on technological development until we moved to Sihwa MTV through the Namdong Industrial Complex in Incheon. When I made a lot of money through exports, I was often tempted to buy a building, but I resisted it. This was due to the belief that the manufacturing industry must compete with cutting-edge technology and facilities.

This company has about 30 researchers. CEO Yoo calls the lab a ‘playground.’ This is because we believe that creative products emerge only when researchers interact with each other in a free atmosphere. There are 48 invention patents (including applications). CEO Yoo said, “We have all the core technologies specialized in manufacturing high-performance valves, such as optimized design technology, low-temperature ion plasma surface hardening heat treatment technology, and thin film coating technology.”

The company's sales, which have about 200 employees, reached 48 billion won in 2017. Due to the economic recession and the US-China trade dispute, it fell back to 32 billion won last year. However, during the recession, we strengthened our research and development and developed high-performance products. Representative examples include the development of process valves and ultra-small fluid transport systems. CEO Yoo said, “As we are seeing results such as high-performance valves, orders are continuing,” and “sales will exceed 100 billion won within a few years.”

[Korea Economy] Nak-Hoon Kim, Director of Hankyung Global Small Business Research Institute nhk@hankyung.com | 2020.04.02 15:14

[ https://www.hankyung.com/article/2020040298101 ]

As the economic downturn and the novel coronavirus infection (COVID-19) situation prolong, difficulties for companies are increasing. However, amidst this, there are companies located in industrial complexes that are preparing for the future through bold facility investment and management innovation. Unilok, which produces high-performance valves, invested 48 billion won and recently completed a new factory in Sihwa MTV and prepared for a leap forward. We also set a vision to reach 100 billion won in sales within a few years.

Pipes pass through the production lines of major factories, including semiconductor factories. This is a pipe that transports fluids, gases, etc. There are valves throughout the pipes. Although it is a small part, it plays a very important role. If the fluid or gas flowing inside is an explosive chemical or harmful gas, it may lead to an accident if it is not properly controlled.

Unilok (CEO Yoo Myung-ho, 63), located in Sihwa MTV (Multi-Techno Valley), is a company that manufactures high-performance valves used in such areas. Many of these valves have been domestically produced one by one, although American or Japanese companies have dominated the domestic market. An ultra-small fluid transportation system was also developed. It is a precision product mainly supplied by Japanese companies. We also domestically produced a high-performance regulator for semiconductors that prevents gas leaks due to corrosion by applying proprietary metal coating technology.

Now, products that surpass the technology of advanced countries have begun to be introduced. The newly developed process valve has a response speed of less than 5/1000 seconds. You can control it in a short amount of time. This means that fluid can be controlled in precise amounts. CEO Yoo explained, “The valve has moved beyond its simple opening and closing function and has become a key component that determines the success or failure of the manufacturing process.”

The company completed construction of a new factory here at the end of last year. It has a land area of approximately 20,000 m2 and a total floor area of 15,000 m2. A factory, office building, and welfare building were built. A site of 7,600 m2 was reserved for expansion. The total investment cost was 48 billion won (based on completion of facility investment), including land purchase, construction, and facility investment. When you enter the third floor of the office building, Sihwa Lake unfolds before your eyes. Across the street, you can see a wide field including the Hwaseong Dinosaur Egg Fossil Site at a glance. The late afternoon sunset is spectacular.

The reason it was located here is because the Korea Industrial Complex Corporation, which sold Sihwa MTV, classified the company's industry as a high-tech industry. Every corner of the factory is a clean space. CEO Yoo said, “Because this product is supplied to a semiconductor factory, the clean room level of our factory is similar to that of a semiconductor factory.” Main domestic customers include Samsung Electronics and SK Hynix. It is exported to over 40 countries in the United States, Europe, Asia, the Middle East, and South America. Transaction partners include companies in the petrochemical, power and energy, semiconductor, bio, and fuel cell fields. We supply it under our own brand, ‘Uni-Lok’.

The company's growth stems from CEO Yoo's obsession with technology development. After graduating from school, he joined a fittings and valves production company in Cheonggyecheon, Seoul and took charge of sales. In this process, he learned product characteristics and later reached a level where he could develop technology. The company was founded in 1984 near Anyangcheon Stream near the Guro Tool Shopping Center in Seoul with one technician and one female employee. We did not let up on technological development until we moved to Sihwa MTV through the Namdong Industrial Complex in Incheon. When I made a lot of money through exports, I was often tempted to buy a building, but I resisted it. This was due to the belief that the manufacturing industry must compete with cutting-edge technology and facilities.

This company has about 30 researchers. CEO Yoo calls the lab a ‘playground.’ This is because we believe that creative products emerge only when researchers interact with each other in a free atmosphere. There are 48 invention patents (including applications). CEO Yoo said, “We have all the core technologies specialized in manufacturing high-performance valves, such as optimized design technology, low-temperature ion plasma surface hardening heat treatment technology, and thin film coating technology.”

The company's sales, which have about 200 employees, reached 48 billion won in 2017. Due to the economic recession and the US-China trade dispute, it fell back to 32 billion won last year. However, during the recession, we strengthened our research and development and developed high-performance products. Representative examples include the development of process valves and ultra-small fluid transport systems. CEO Yoo said, “As we are seeing results such as high-performance valves, orders are continuing,” and “sales will exceed 100 billion won within a few years.”

[Korea Economy] Nak-Hoon Kim, Director of Hankyung Global Small Business Research Institute nhk@hankyung.com | 2020.04.02 15:14

[ https://www.hankyung.com/article/2020040298101 ]

top

top