Category

- Instruments | Valve | Check Valve

- Dimensions

- How To Order

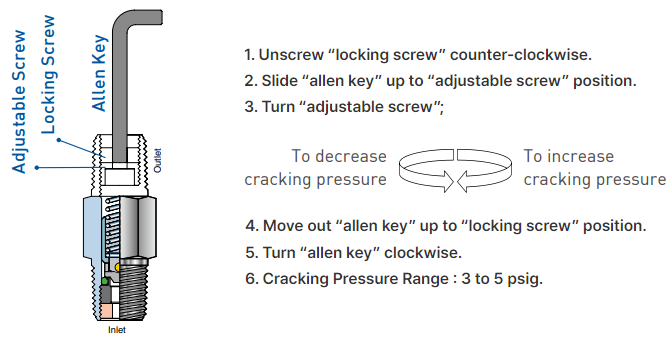

- Adjustment of Cracking Pressure

- Features

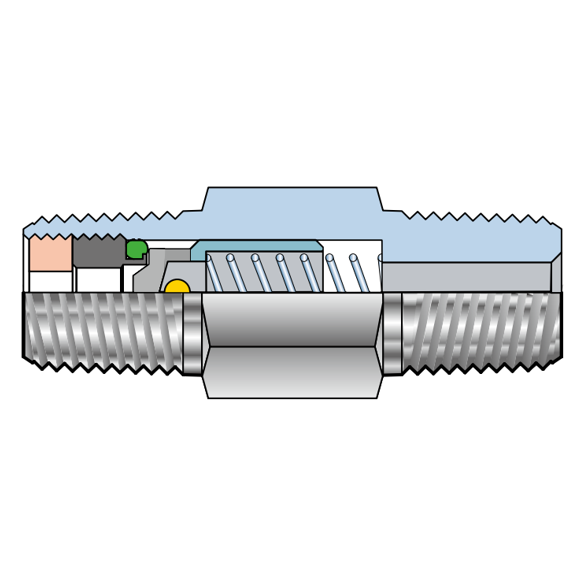

Dimensions

| Dimensions | ||||||

| Part No. | End Connections | CV | Dimensions (mm) | |||

| Inlet | Outlet | L | h | |||

| VC3CA1 | F-04N- | 1/4" Female NPT | 0.35 | 75.7 | 19.05 | |

| M-04N- | 1/4" Male NPT | 42.2 | 14.28 | |||

How To Order

UNILOK VC series check valves are ordered by part number as shown below.

Example: The following part number, VC31U-04T-SS-01 is designated for VC3 series check valve with both 1/4", UNILOK tube fitting, 1psig cracking pressure, 316SS.

| V | C3CA1 | F | - | 04T | - | SS | - | 01 | - | |

| UNILOK Valve | Valve Type | Connection type | Connection Size | Body Materials | Cracking Pressure | O-ring Materials | ||||

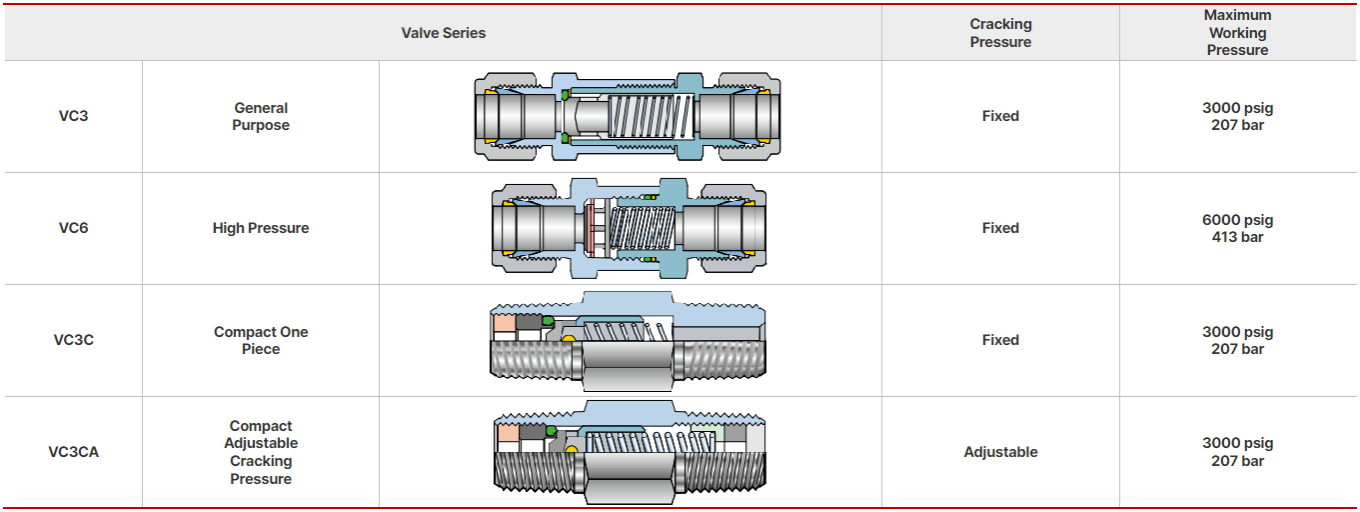

| Valve Type | Connection Size | Body Materials | ||||||||||||||||

| C3 | 3000psig Fixed CP | Fractional(Inch) Tube O.D. Designation | SS | 316SS | ||||||||||||||

| C6 | 6000psig Fixed CP | Tube O.D. | inch | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | BS | Brass | |||||||

| C3C | 3000psig Compact Fixed CP | mm | 3.17 | 6.35 | 9.52 | 12.70 | 19.05 | 25.40 | MO | Alloy 400 | ||||||||

| C3CA | 3000psig Compact Adjustable CP | Designator | 02T | 04T | 06T | 08T | 12T | 16T | ||||||||||

| CP - Cracking Pressure | Cracking Pressure | |||||||||||||||||

| Metric Tube O.D. Designation | 1/3 | 1/3 psig | ||||||||||||||||

| Connection Type | Tube O.D. | mm | 3 | 6 | 8 | 10 | 12 | 25 | 01 | 1 psig | ||||||||

| U | UNILOK Tube Fitting | Designator | M03T | M06T | M08T | M10T | M12T | M25T | 03 | 3 psig | ||||||||

| F | Female NPT or ISO7/1(PT) | 10 | 10 psig | |||||||||||||||

| M | Male NPT or ISO7/1(PT) | Pipe Size Designation (NPT or ISO7/1-PT) | 25 | 25 psig | ||||||||||||||

| Pipe Size | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 100 | 100 psig | ||||||||||

| Designator | 02N/R | 04N/R | 06N/R | 08N/R | 12N/R | 16N/R | ||||||||||||

| O-ring Materials | ||||||||||||||||||

| None | FKM | |||||||||||||||||

| EPDM | Ethylene Propylene | |||||||||||||||||

| NBR | Buna N | |||||||||||||||||

| P | Neoprene | |||||||||||||||||

| K | Kalrez | |||||||||||||||||

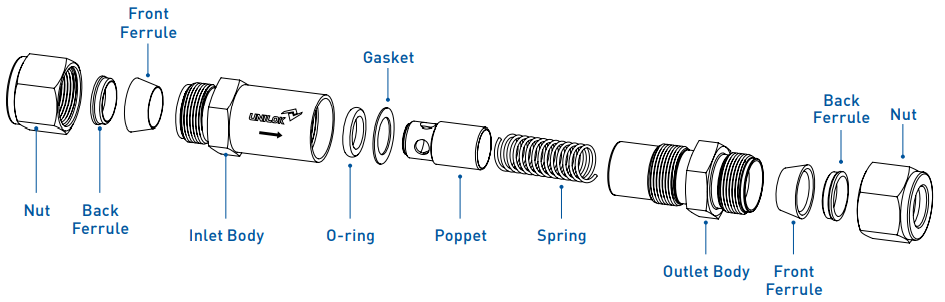

| Seal kits and spring kits are available for retrofit or maintenance. Contact UNILOK local distributors. | ||||||||||||||||||

Features

Cleaning

UNILOK valves are free from machine oils, loose particles, and grease throughout the cleaning process.

Testing

Every check valve is 100% factory tested with nitrogen for cracking and reseal performance.

Special cleaning for high-purity applications is available upon request.

Important Notification

Proper installation, materials compatibility, operation and maintenance of these valves are the responsibility of the user.

The total system design must be taken into consideration to ensure optimal performance and safety.

UNILOK check valves are designed for directional flow control only.

top

top