Category

- Instruments | PTFE Fittings | Reducing Union

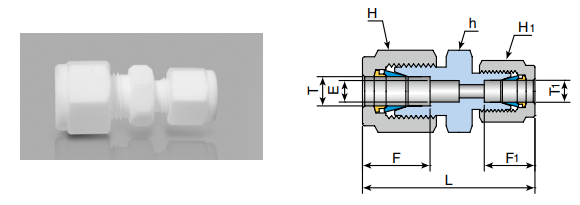

- Dimensions

- How to order

- Features

Dimensions

| Connects Fractional Tube | Connects Metric Tube | |||||||||||||||||||

| Part No. | Tube O.D. | Dimensions (mm) | Part No. | Tube O.D. | Dimensions (mm) | |||||||||||||||

| T1 | T2 | E (Min) | h | H | H1 | F | F1 | L | T1 | T2 | E (Min) | h | H | H1 | F | F1 | L | |||

| URU-0604-TF | 3/8 | 1/4 | 4.8 | 20.63 | 20.63 | 15.87 | 17.0 | 15.2 | 45.0 | URU-M10M06-TF | 10 | 6 | 4.8 | 19.05 | 19.05 | 15.87 | 17.20 | 15.2 | 45.4 | |

| URU-0804-TF | 1/2 | 1/4 | 4.8 | 25.4 | 25.40 | 15.87 | 22.9 | 15.2 | 48.5 | URU-M12M06-TF | 12 | 6 | 4.8 | 25.40 | 25.40 | 15.87 | 22.90 | 15.2 | 48.5 | |

| URU-0806-TF | 1/2 | 3/8 | 7.0 | 25.4 | 25.40 | 20.63 | 22.9 | 17.0 | 49.3 | URU-M12M10-TF | 12 | 10 | 7.0 | 25.40 | 25.40 | 19.05 | 22.90 | 17.2 | 49.7 | |

How to order

UNILOK PTFE fittings are ordered by part number as shown below.

Example: The following part number, UMC-0404N-TF is designated for Male Connector, 1/4"O.D. x 1/4" M-NPT, PTFE.

| U | MC | - | 04 | 04 | N | - | TF |

| UNILOK Tube Fittings | Fitting Type | Tube O.D. | Pipe Size | Thread Type | PTFE Materials | ||

| Fractional(Inch) Tube O.D. Designation | Pipe Size Designation (NPT or ISO7/1-PT) | |||||||||||

| Tube O.D. | inch | 1/4 | 3/8 | 1/2 | Pipe Size | 1/4 | 3/8 | 1/2 | ||||

| mm | 6.35 | 9.52 | 12.70 | Designator | 04 | 06 | 08 | |||||

| Designator | 04 | 06 | 08 | |||||||||

| Thread Type Designation | ||||||||||||

| Metric Tube O.D. Designation | Thread Type | Designator | ||||||||||

| Tube O.D. | mm | 6 | 8 | 10 | 12 | NPT | National Standard Pipe Thread | N | ||||

| Designator | M06 | M08 | M10 | M12 | ISO 7/1 | Taper Pipe Thread | R | |||||

Features

Maximum working pressure: 125 psi (8.6 bar)

Maximum working temperature: 100℃ (212℉)

Standard type fitting with a simple structure and compact design. Easy assembly taper swaging sealing system. Applicable sizes:

1/4" ~ 1/2" O.D. (6mm ~ 12mm O.D.).

Applications

Ultrapure or corrosive chemical applications.

Cleaning

UNILOK PTFE fittings are free from machine oils, loose particles, and grease throughout the close cleaning process.

Special cleaning for high-purity applications is available upon request.

top

top