Back to previous page

![이미지]()

RCM3 series

RCM3 series

Category

- UHP | Regulator | RCM3 series

- Dimensions

- How To Order

- Specification

- Features

How To Order

| RCM3 | C | - | 04F | - | 11 | 0 | - | 2 | ||||

| Regulator Type | Connection Type | Connection Size | Inlet / Outlet Pressure | Gauge Port Option | Outlet Gauge | Body Material | Surface Finish | Trim Material | Seat Material | |||

| Regulator Type | Outlet Pressure Range | Body Material | |||||||||||

| RCM3 | RCM3 Series | 0 | 1~30 psig / 0.1~2.1 bar | 2 | 316L VAR Stainless Steel | ||||||||

| 1 | 1~60 psig / 0.1~4.1 bar | 4 | 316L Stainless Steel | ||||||||||

| Connection Type | 2 | 1~100 psig / 0.1~6.9 bar | |||||||||||

| C-*M | Male UCR Swivel | 3 | 1~150 psig / 0.1~10.3 bar | Internal Surface Finish | |||||||||

| C-*MX | Male UCR Fixed | None | EP – Electro Polished | ||||||||||

| C-*F | Female UCR Swivel | Gauge Port Option | BA | BA | |||||||||

| WB-*T | Tube Butt Weld | 0 | None (Fig. A) | ||||||||||

| 1 | 1/4“ Male Swivel (Fig. B) | Trim Material | |||||||||||

| Connection Size | 2 | 1/4“ Female Swivel (Fig. B) | None | 316 SS | |||||||||

| 04 | 1/4 inch | H | Hastelloy® | ||||||||||

| Outlet Gauge | |||||||||||||

| Maximum Inlet Pressure | None | No Gauge | Seat Material | ||||||||||

| 1 | 500 psig (0.1 Cv) | 0 | 0~30 psig | None | PCTFE | ||||||||

| 2 | 250 psig (0.1 Cv) | 1 | 0~60 psig | T | PTFE | ||||||||

| 4 | 500 psig (0.17 Cv) | 2 | 0~100 psig | F | PFA | ||||||||

| 5 | 250 psig (0.17 Cv) | 3 | 0~160 psig | ||||||||||

Specification

| Pressure Ratings | |||||

| Per criteria of ANSI/ASME B31.3 | Media Contact Materials | ||||

| Max. Inlet Pressure | 250, 500 psig (17.3, 34.5 bar) | Body | 316L Stainless Steel | ||

| Diaphragm | Hastelloy® | ||||

| Outlet Pressure Range | 30, 60, 100, 150 psig (2.1, 4.1, 6.9, 10.3 bar) | Seat | PCTFE (Optional PTFE, PFA) | ||

| Poppet | 316 Stainless Steel or Inconel® | ||||

| Design Proof Pressure | 150% of maximum rated | Rear Seal | 316L Stainless Steel or Hastelloy® | ||

| Operating Temperature | Internal Surface Finish | ||||

| PCTFE Seat | -40~60℃ (-40℉~140℉) | Designator | Surface Finish(µm) | ||

| PTFE Seat | -40~71℃ (-40℉~160℉) | Average | Maximum | ||

| PFA Seat | -40~71℃ (-40℉~160℉) | BA | < 0.4 | < 1.6 | |

| EP | < 0.125 | < 0.4 | |||

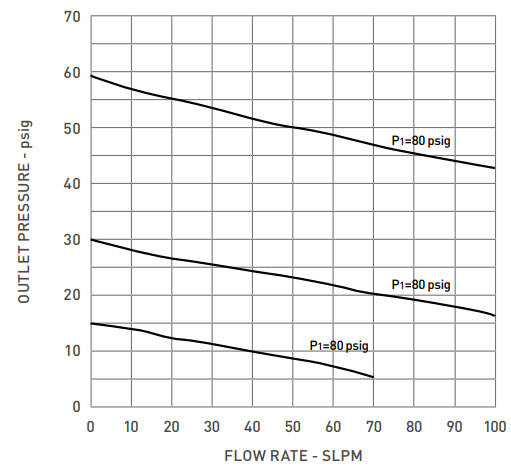

| Flow Capacity | |||||

| Flow Capacity | 0.1 Cv (Optional 0.17 Cv) | ||||

| Helium Leak Test | |||||

| Inboard Leak Rate | 1x10-9 atm cc/sec | ||||

Features

· The RCM3 series, an ultra high purity pressure reducing regulator, provides precise performance and repeatability

· Compact size

· Low internal volume

· Metal to metal diaphragm seals provide enhanced leak integrity

· Optimum performance and cleanliness at a great value

· All performed in Class 100 and Class 10 clean rooms.

Flow Chart

top

top