Category

- UHP | Fittings | Weld & Metal Face Seal Fittings | Weld Fittings

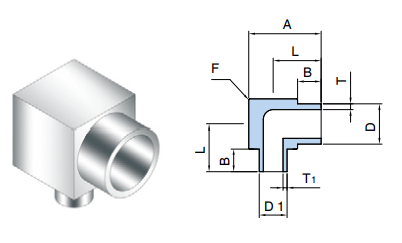

- Dimensions

- How To Order

- Specification

- Features

Dimensions

| Part No. | Tube

O.D. D | Tube

W.T. T | Tube

O.D. D1 | Tube

W.T. T1 | Dimension

(mm) | Body Cube | |||||||

| inch | mm | inch | mm | inch | mm | inch | mm | A | B | L | F | ||

| CMRE-0402- | 1/4 | 6.35 | 0.039 | 1.00 | 1/8 | 3.17 | 0.028 | 0.71 | 14.29 | 6.35 | 10.32 | 7.94 | |

| CMRE-0604- | 3/8 | 9.52 | 1.00 | 1/4 | 6.35 | 0.039 | 1.00 | 17.46 | 11.91 | 11.11 | |||

| CMRE-0804- | 1/2 | 12.70 | 0.049 | 1.24 | 1/4 | 6.35 | 1.00 | 20.64 | 13.50 | 14.29 | |||

| CMRE-0806- | 1/2 | 12.70 | 0.049 | 1.24 | 3/8 | 9.52 | 1.00 | ||||||

How To Order

UNILOK weld fittings are ordered by part number as shown below.

Example: The following part number, CLGS-0804-SM-EP is designated for Long Gland S, 1/2"UCR x 1/4"TBW", Single Melting 316LSS, EP.

| C | MRE | - | 08 | 04 | - | DM | - | EP |

| UNILOK Clean Fittings | Fitting Type | Connection Size & Type | Connection Size & Type | Materials | Surface Finish Level | |||

| Connection Size & Type | Materials | |||||||||||

| Fractional(Inch) Tube O.D. Designation | DM | 316LSS-SEMI F20 | ||||||||||

| Tube O.D. | inch | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | SL | 316LSS | |||

| mm | 3.17 | 6.35 | 9.52 | 12.70 | 19.05 | 25.40 | NI | Nickel | ||||

| Designator | 02 | 04 | 06 | 08 | 12 | 16 | ||||||

| Surface Finish Level | ||||||||||||

| UCR (Metal Face Seal) Size Designator | BA | BA - Bright Annealing | ||||||||||

| Pipe Size | 1/4 | 1/2 | 3/4 | 1 | EP | EP - Electro Polished | ||||||

| Designator | 06 | 08 | 12 | 16 | ||||||||

| Pipe Size Designation (NPT or ISO7/1(PT)) | ||||||||||||

| Pipe Size | 1/4 | 3/8 | 1/2 | 3/4 | 1 | |||||||

| Designator | 04N/R | 06N/R | 08N/R | 12N/R | 16N/R | |||||||

Specification

| Materials | Pressure Ratings | Temperature Ratings | |||||||||||

| Materials | Specification | Tube O.D. | Wall Thickness | Pressure Rating | Components | Materials | ℉ | ℃ | |||||

| Glands, Unions, Weld Fittings | psig | bar | Fittings | 316LSS-SEMI F20 | 1000 | 537 | |||||||

| 316LSS-SEMI F20 | ASTM A276 / A479 | 1/4" | 1.00mm | 5200 | 359 | 316LSS | |||||||

| 316LSS | 0.89mm | Gaskets | 316LSS | 1000 | 537 | ||||||||

| Nuts, Plugs, Caps, UCR Threaded Fittings | 3/8" | 1.00mm | 3350 | 231 | Nickel | 600 | 315 | ||||||

| 316LSS | Forging - ASTM A182 Bar Stock - ASTM A276 / A479 | 0.89mm | |||||||||||

| 1/2" | 1.24mm | 3750 | 259 | ||||||||||

| Gaskets | 3/4" | 1.65mm | 3350 | 231 | |||||||||

| Nickel | ASTM B162 | 1" | 1.65mm | 2400 | 265 | ||||||||

| 316LSS | ASTM A240 | 0.89mm(0.035") wall thick fittings are available upon request. When ordering, be sure to add -A to the part number. | |||||||||||

| Both 316LSS-SEMI F20 and 316LSS are UHP[Ultra High Purity] 316LSS material with low Sulfur and Manganese in comply with SEMI F20. | |||||||||||||

Helium Leak Test

UNILOK fittings are rated to a helium leak rate of less than 1x10-9 mbar.l/sec and tested in accordance with SEMA-90120391B-STD and SEMI F1-96.

Particle Contribution Test

According to ASTM F1394-92.

Moisture Contribution Test

According to SEMA-90120397B-STD.

Cleaning

All components are precisely cleaned with 18㏁ deionized water after the passivation procedure.

Reference specification : SEMI E49.6.

Assembling

According to SEMI E49.6.

Packaging

Each component is double bagged to ensure component cleanliness and to protect them from environmental contamination.

Referenced specification : SEMI E49.1.

Features

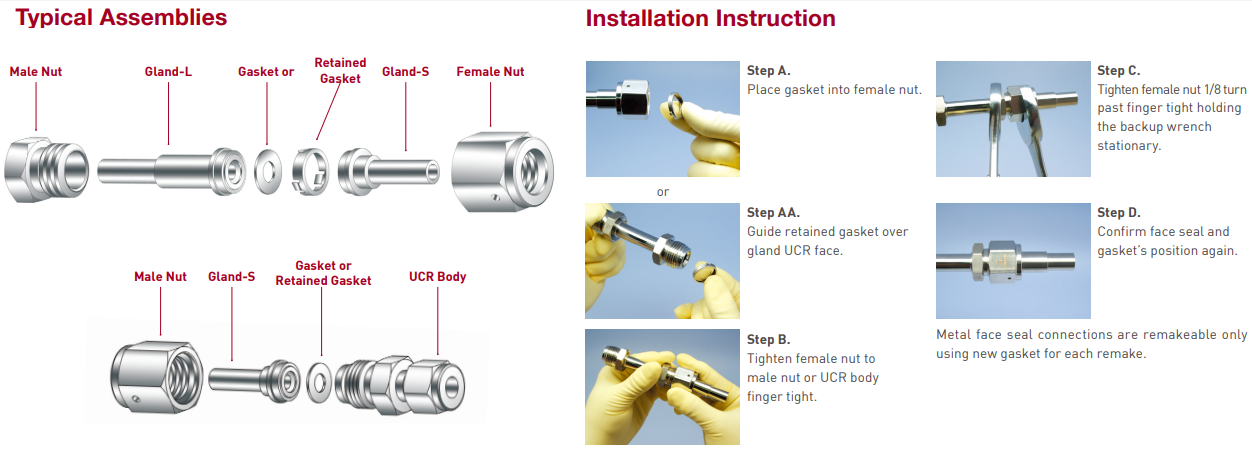

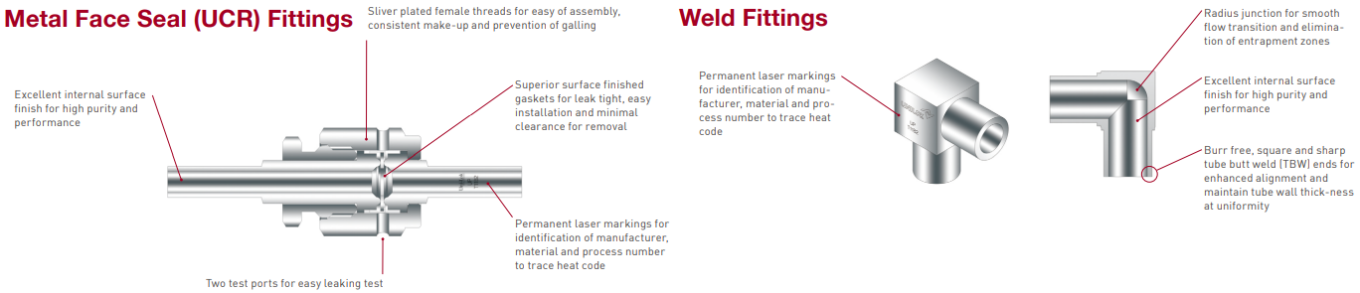

UNILOK® Weld & Metal Face Seal (UCR) fittings are designed and manufactured as high performance and high purity components by our own know-how to be accumulated throughout the years. UNILOK® guarantees high quality butt welding between tube and fittings as well as leak free assembly for critical applications.

Internal Surface Finish Levels

| Designator | Surface Finish(㎛) | |

| Average | Maximum | |

| BA | < 0.4 | < 1.6 |

| EP | < 0.125 | < 0.4 |

| Reference Specification : SEMA-90120400B | ||

Surface Analysis

SEM, ESCA/XPS, AES analysis for all electro polished products are used to measure surface cleanliness and anticorrosion requirements in accordance with SEMA specifications.

SEM - SEMA 90120401B-STD

ESCA/XPS - SEMA 90120403B-STD

AES - SEMA 91060573B-STD

Plating

Female nuts are silver plated for easy of assembly, consistent make-up, prevention of galling and reduction of the torque required for fitting assembling.

top

top