Category

- UHP | Other | Vacuum Generator

- Ordering Information & Dimensions

- How To Order

- Specification

- Features

How To Order

| VCGC | - | 04 | M | 08 | M | 04 | M | - | SL | - | BA |

| Valve Type | Inlet Connection Size | Connection Type | Outlet Connection Size | Connection Type | Vacuum Connection Size | Connection Type | Body Material | Surface Finish Level | |||

| Valve Type | Inlet Connection Size | Materials | |||||||||||

| VCG | Vacuum Generator | Fractional(Inch) Tube O.D. Designation | DM | 316LSS-SEMI F20 | |||||||||

| Tube O.D | inch | 1/4 | 3/8 | 1/2 | SL | 316L SS | |||||||

| Connection Type | mm | 6.35 | 9.52 | 12.70 | |||||||||

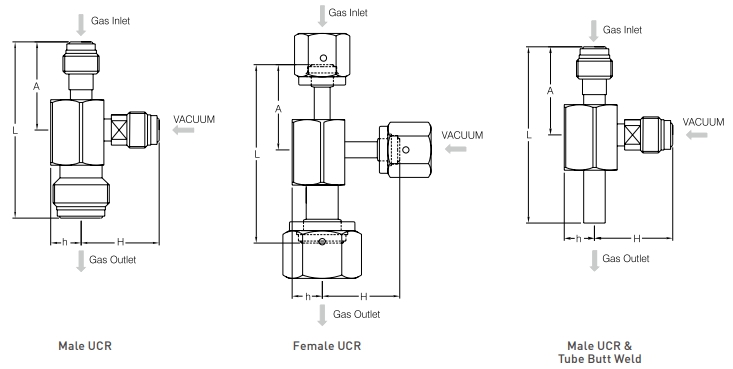

| C-*M | Male UCR | Designator | 04T | 06T | 08T | Surface Finish Level | |||||||

| C-*F | Female UCR | BA | BA - Bright Annealing | ||||||||||

| WB- | Tube Butt Weld | UCR Size Designator | EP | EP-Electro Polished | |||||||||

| UCR Size | 1/4 | 1/2 | |||||||||||

| Designator | 04 | 08 | |||||||||||

Specification

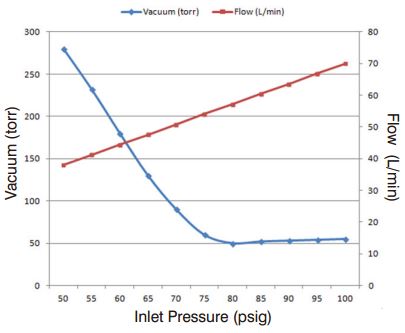

| Orifice Size | 1.35mm |

| Ultimate Vacuum | 50torr (66.7mbar) |

| Gas Flow at Ultimate | 60 l/min |

| Gas Pressure at Ultimate | 80psig |

| Optimize working Pressure | 80~100psig |

| Max. Working Pressure | 150psig (10kgf/cm²) |

| Operating Temperature | 0~150℃ |

Helium Leak Test

Every VCG series are inboard helium leak tested to a rate of 1x10-9 cm3 /sec.

Particle Contribution Test

According to ASTM F1394-92.

Moisture Contribution Test

According to SEMA-90120397B-STD.

Vacuum and Flow Chart

Cleaning

All components are precisely cleaned with 18㏁ deionized water after the passivation procedure in accordance with our own UHP cleaning process Reference specification : SEMI E49.6.

Packaging

Each component is double bagged to ensure component cleanliness and to protect them from environmental contamination.

Referenced specification : SEMI E49.1.

Features

· Function of the pressure of the purge gas which flows through the generator.

· Low space requirement.

· Extremely fast evacuation time.

· All performed in class 100 and class 10 clean rooms.

· Stainless Steel 316L construction.

top

top