范畴

- Instruments | Valve | High Pressure Bar Stock Needle Valves

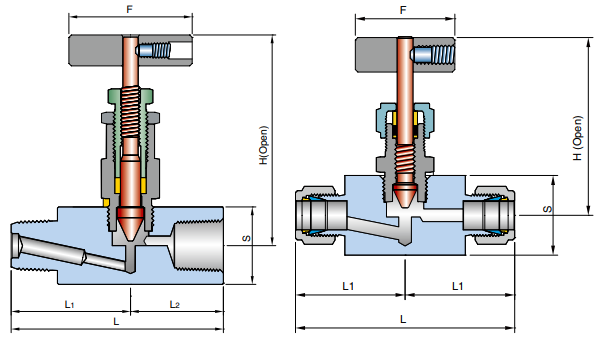

- Dimensions

- How To Order

- Pressure - Temperature Rating

- Features

Dimensions

| Part No. | End Connections | Orifice | CV | Dimensions (mm) | |||||||

| Inlet | Outlet | L | L1 | S | F | H | L2 | ||||

| VN61 | U-04T- | 1/4" UNILOK | 4.0 | 0.35 | 76.4 | 38.2 | 25.4 | 45.0 | 56.7 | ||

| U-06T- | 3/8" UNILOK | 75.8 | 37.9 | ||||||||

| U-08T- | 1/2" UNILOK | 81.6 | 40.8 | ||||||||

| U-M06T- | 6mm UNILOK | 76.2 | 38.1 | ||||||||

| U-M08T- | 8mm UNILOK | ||||||||||

| U-M10T- | 10mm UNILOK | ||||||||||

| U-M12T- | 12mm UNILOK | ||||||||||

| VN62 | F-04N- | 1/4" Female NPT | 4.0 | 0.35 | 76.2 | 38.1 | 32.0 | 50.6 | 86.5 | 38.1 | |

| F-06N- | 3/8" Female NPT | ||||||||||

| F-08N- | 1/2" Female NPT | ||||||||||

| MF-04N- | 1/4" Male NPT | 1/4" Female NPT | |||||||||

| MF-06N- | 3/8" Male NPT | 3/8" Female NPT | 82.2 | 44.1 | 32.0 | ||||||

| MF-08N- | 1/2" Male NPT | 1/2" Female NPT | 87.1 | 49.0 | 32.0 | ||||||

How To Order

UNILOK VN6 series needle valves are ordered by part number as shown below.

Example: The following part number, VN62MF-04N-SS is designated for VN6 series needle valve with1/4" male NPT to 1/4" female NPT, 316SS.

| V | N62 | U | - | 04N | - | SS | - | - | ||

| UNILOK Valve | Valve Type | Connection type | Connection Size | Body Materials | Stem Type | Packing Materials | ||||

| Connection Type | Metric Tube O.D. Designation | Body Materials | ||||||||||||||

| U | UNILOK Tube Fitting | Tube O.D. | mm | 6 | 8 | 10 | 12 | SS | 316SS | |||||||

| F | Female NPT or ISO7/1(PT) | Designator | M06T | M08T | M10T | M12T | MO | Alloy 400 | ||||||||

| M | Male NPT or ISO7/1(PT) | |||||||||||||||

| Pipe Size Designation (NPT or ISO7/1-PT) | Stem Type | |||||||||||||||

| Connection Size | Pipe Size | 1/4 | 3/8 | 1/2 | None | Vee Stem | ||||||||||

| Fractional(Inch) Tube O.D. Designation | Designator | 04N/R | 06N/R | 08N/R | S | Soft Seat Stem | ||||||||||

| Tube O.D. | inch | 1/4 | 3/8 | 1/2 | ||||||||||||

| mm | 6.35 | 9.52 | 12.70 | Packing Materials | ||||||||||||

| Designator | 04T | 06T | 08T | None | PTFE | |||||||||||

| PK | PEEK | |||||||||||||||

| GF | Grafoil | |||||||||||||||

Pressure - Temperature Rating

| Body Material | Stem | PTFE packing | Packing Material | Body Material | Temperature

Rating | Pressure Rating @ Max. Temperature | ||||||

| Temperature Rating | Pressure Rating @ 38℃ | |||||||||||

| ℃ | ℉ | psig | bar | ℃ | ℉ | psig | bar | |||||

| 316SS | Vee (metal to metal) | -54~232 | -65~450 | 6000 | 413 | PTFE | 316SS | -54~232 | -65~450 | 4130 | 285 | |

| Soft-seat (Kel-F) | -54~93 | -65~200 | Alloy 400 | 3970 | 274 | |||||||

| Alloy 400 | Vee (metal to metal) | -54~232 | -65~450 | 5000 | 345 | PEEK | 316SS | -54~315 | -65~600 | 3760 | 260 | |

| Soft-seat (Kel-F) | -54~93 | -65~200 | Alloy 400 | -54~260 | -65~500 | 3960 | 273 | |||||

| For the service with aromatic heat transfer fluids or concentrated sulfuric and nitric acids, PEEK is not recommended. | ||||||||||||

Application

Severe service application, steam service in power plant, hot condensates.

Sour Environment Services

UNILOK valves are comply with NACE MR 0175/ISO 15156 for sour oilfield application or NACE MR-0103 for petroleum refining operations.

To order, add -N to the end of part number.

Cleaning

UNILOK valves are free from machine oils, loose particles and grease throughout the close cleaning process.

Testing

Every valve is 100% factory tested with air and nitrogen at 1000psig(69bar) for leakage at the seat and packing.

Each test is performed to a maximum allowable leak rate of 0.1scc/min.

Important Notification

Proper installation, materials compatibility, operation and maintenance of these valves are the responsibility of the user. The total system design must be taken into consideration to ensure optimal performance and safety.

The packing adjustment may be required during the valve's service life.

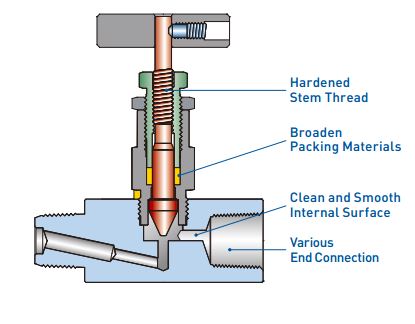

Features

Pressure rating up to 6000 psig (413 bar) @38℃ (100℉).

Temperature rating from -53℃ (-65℉) to 232℃ (450℉) with standard PTFE packing, up to 315℃ (600℉) with PEEK packing.

High-temperature application is available with Grafoil packing, up to 648℃ (1200℉).

Compact body design.

Hardened stem threads and forged body for long cycle life.

Integral bonnet design to eliminate unintentional stem back-out.

Stop pin to prevent accidental bonnet disengagement.

top

top