范畴

- UHP | Valves | Diaphragm Valves

PDF 다운로드

- Dimensions

- How To Order

- Specification

- Features

How To Order

UNILOK VCD series valves are ordered by part number as shown as below.

Example : The following part number,VCDLC 04M-PO-SL-EP is designated for Low Pressure Diaphragm Valve, both 1/4” Male UCR, Pneumatic

Normal Open Operation, 316LSS, EP.

| VC | DL | C | - | - | 04 | M | - | PC | R | - | - | SL | - | EP | H | - | S001 | - | PI | - | PN | ||

| ① Type | ② Valve Type | ③ Connection Type | ④ Flow Path Pattern | ⑤ Connectin Size | ⑥ Connectin Type (In detail) | ⑦ Operation (Operation Type) | ⑧ Handle & Label Color | ⑨ Bleed Option | ⑩ Material | ⑪ Surface Finish Level | ⑫ Option-2 (Open/Close Color) | ⑬ Option-3 (Overall Body Length Size) | ⑭ Option-4 (Seat Material) | ⑮ Option-5 (Panel Nut) | |||||||||

| ① Type | ⑥ Connectin Type (In detail) | ⑪ Surface Finish Level | |||||||||||||

| VC | UHP | T | Tube(U-**T, WB-**T) | BA | Bright Annealing | ||||||||||

| M | Male UCR(C-**M) | EP | Electro Polished | ||||||||||||

| ③ Connection Type | F | Female UCR(C-**F) | |||||||||||||

| U | Unilok Tube Fitting | ⑫ Option-2 (Open/Close Color) | |||||||||||||

| C | UHP UCR Fitting | ⑦ Operation (Operation type) | None | Open-Red, Close-Blue | |||||||||||

| WB | Butt Weld | RMS | H | Open-Blue, Close-Red | |||||||||||

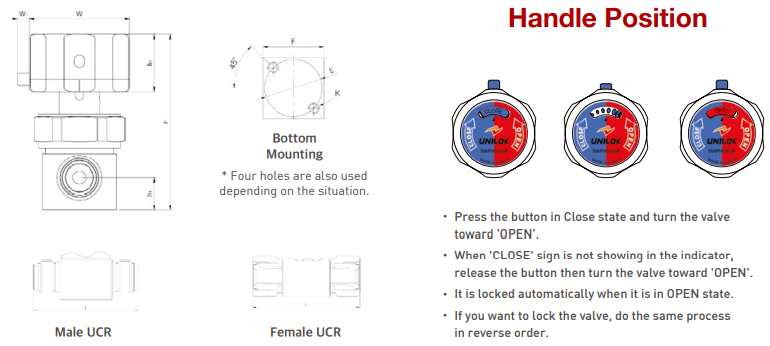

| MI | Lock Handle | ||||||||||||||

| ⑤ Connectin Size | * RMS can only be used with forged types | ⑭ Option-4(Seat Material) | |||||||||||||

| 04 | 1/4" | None | PCTFE(-10~80°C) | ||||||||||||

| 06 | 3/8" | ⑩ Material | PI / V | PI / VESPEL(-10~150°C) | |||||||||||

| 08 | 1/2" | DM | 316LSS - SEMI F20 | PFA / F | PFA(-10~150°C) | ||||||||||

| SL | 316LSS | ||||||||||||||

Specification

| Size | 1/4" | 1/2" | |

| Orifice Size | 4.3 | 6.5 | |

| Cv Value | 0.3 | 0.7 | |

| Max. Working Pressure | 10 bar (145 psig) | ||

| Max. Working Temperature | -10~80°C (14~176°F) | ||

| Handle Operation Angle | 270° | ||

| Internal Leakage Allowance - He | ≤1x10-9 atm.cc/s | ||

| External Leakage Allowance - He | ≤1x10-9 atm.cc/s | ||

Features

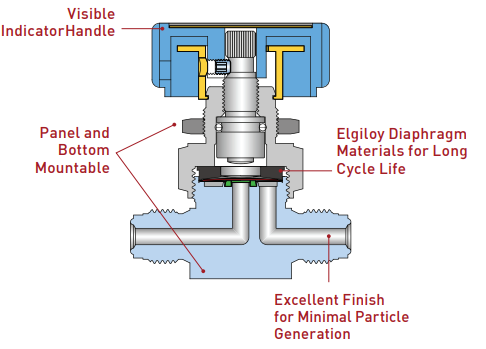

A compactly designed body with minimal dead space.

Body materials comply with SEMI F-20, “Specification for 316LSS Materials for UHP (Ultra High Purity) Grade Semiconductor Manufacturing Applications”

Maximum flow capacity

Minimal particle generation

Minimal contributions of moisture, oxygen and hydrocarbon with UNILOK’s own special cleaning process in a certified clean room

Excellent finish level of wetted areas with UNILOK’s own electro polish process

Elgiloy® diaphragm material with strong durability as well as corrosion resistance for long cycle life

PCTFE seat material with remarkable chemical and thermal resistance

top

top