范畴

- UHP | Valves | Bellows Valves

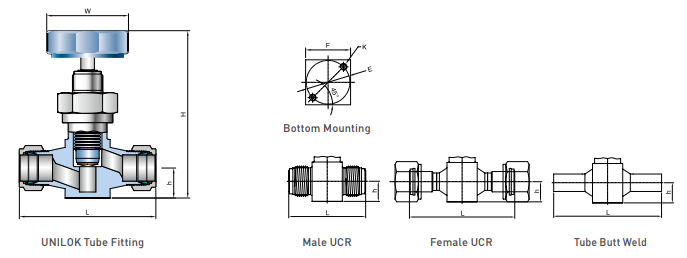

- Dimensions

- How To Order

- Specification

- Features

How To Order

UNILOK VCB series valves are ordered by part number as shown below.

Example : The following part number, VCBLU-08T SL-BA is designated for Low Pressure Bellows

Valve, both 1/2” UNILOK Tube Fittings, 316LSS, BA.

| VC | BL | U | - | 08T | - | - | SL | - | BA | |

| UNILOK Clean Valves | Valve Type | Connection Type | Connection Size | Operation Type | Material | Surface Finish Level | ||||

| Valve Type | Connection Size | Operation Type | ||||||||||||||

| BL | Standard Low Pressure | Fractional(Inch) Tube O.D. Designation | None | Manual Indicator Handle | ||||||||||||

| BF | Forged Body | Tube O.D. | inch | 1/4 | 3/8 | 1/2 | 3/4 | 1 | PO | Pneumatic - Normal Open | ||||||

| mm | 6.35 | 9.52 | 12.70 | 19.05 | 25.40 | PC | Pneumatic - Normal Close | |||||||||

| Connection Type | Designator | 04T | 06T | 08T | 12T | 16T | ||||||||||

| U | UNILOK Tube Fitting | Materials | ||||||||||||||

| C-*M | Male UCR | Pipe Size Designation (NPT or ISO7/1-PT) | DM | 316LSS-SEMI F20 | ||||||||||||

| C-*F | Female UCR | Pipe Size | 15A | 20A | 25A | SL | 316LSS | |||||||||

| WB- | Butt Weld -Tube | Designator | 15A | 20A | 25A | |||||||||||

| WB-*P | Butt Weld - Pipe | Surface Finish Level | ||||||||||||||

| FL | Flanged | UCR (Metal Face Seal) Size Designator | BA | BA - Bright Annealing | ||||||||||||

| Pipe Size | 1/4 | 1/2 | 3/4 | EP | EP - Electro Polished | |||||||||||

| Designator | 04 | 08 | 12 | |||||||||||||

Specification

| Size | 3/4" | ||

| Orifice Size | 12 | ||

| Cv Value | 2.6 | ||

| Max. Working Pressure | 10 bar (145 psig) | ||

| Max. Working Temperature | -10~80℃ (14~176℉) | ||

| nternal Leakage Allowance - He (Holding Time - Min 30 sec) | ≤4x10-9 atm.cc/s | ||

| External Leakage Allowance - He (Holding Time - Min 1 min) | ≤4x10-9 atm.cc/s |

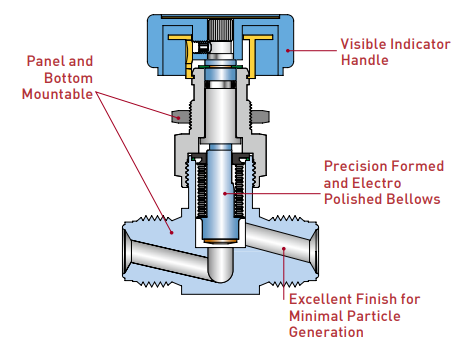

Features

The body is compactly designed with minimal dead space. The body material complies with SEMI F-20, "Specification for 316LSS Materials for UHP (Ultra High Purity) Grade Semiconductor Manufacturing Applications."

The valve features low actuation torque and minimal particle generation. It offers minimal contributions of moisture, oxygen, and hydrocarbons due to UNILOK's special cleaning process in a certified clean room. The wetted areas have an excellent finish level thanks to UNILOK's electro-polishing process. The 316LSS precision-formed and electro-polished bellows are designed for a long cycle life. The PCTFE stem tip material provides remarkable chemical and thermal resistance. Both panel and bottom mounting options are available.

Helium Leak Test

Every valve in the VCB series is inboard helium leak tested to a rate of 4x10^-9 atm.cc/s at the seat and all seals.

Particle Contribution Test

Performed in accordance with ASTM F1394-92.

Moisture Contribution Test

Conducted according to SEMI 90120397B-STD.

Assembling

In compliance with SEMI E49.6.

Cleaning

All components are precisely cleaned with 18 MΩ deionized water following the passivation procedure, in accordance with our own UHP cleaning process. Reference specification: SEMI E49.6.

Packaging

Each component is double-bagged to ensure cleanliness and protect against environmental contamination. Referenced specification: SEMI E49.1.

Important Notification

The proper installation, material compatibility, operation, and maintenance of these valves are the responsibility of the user. The total system design must be considered to ensure optimal performance and safety.

The overall process of testing, cleaning, assembling, and packaging for every valve in the VCB series is performed in a certified clean room.

top

top