返回上一页

![이미지]()

RCTS2 series

Tied Diaphragm

范畴

- UHP | Regulator | RCTS2 series

- Dimensions

- How To Order

- Specification

- Features

How To Order

| RCTS2 | C | - | 08F | - | 22 | 2 | 2 | - | 2 | ||||

| Regulator Type | Connection Type | Connection Size | Inlet / Outlet Pressure | Gauge Port Option | Outlet Gauge | Inlet Gauge | Body Material | Surface Finish | Trim Material | Seat Material | |||

| Regulator Type | Gauge Port Option | Inlet Gauge | |||||||||||

| RCTS2 | RCTS2 Series | 0 | None (Fig. A) | None | No Gauge | ||||||||

| 1 | 1/4“ Internal UCR (Fig. B) | A | 0~600 psig | ||||||||||

| Connection Type | 2 | 1/4“ Internal UCR (Fig. C) | B | 0~1000 psig | |||||||||

| C-*M | Male UCR Swivel | 3 | 1/4“ Internal UCR (Fig. D) | C | 0~2500 psig | ||||||||

| C-*MX | Male UCR Fixed | 4 | 1/4“ Male Swivel (Fig. B) | D | 0~3500 psig | ||||||||

| C-*F | Female UCR Swivel | 5 | 1/4“ Male Swivel (Fig. C) | E | 0~4000 psig | ||||||||

| WB-*T | Tube Butt Weld | 6 | 1/4“ Male Swivel (Fig. D) | ||||||||||

| U-*T | UNILOK Tube Fitting | 7 | 1/4“ Female Swivel (Fig. B) | Body Material | |||||||||

| 8 | 1/4“ Female Swivel (Fig. C) | 2 | 316L VAR Stainless Steel | ||||||||||

| Connection Size | 9 | 1/4“ Female Swivel (Fig. D) | 4 | 316L Stainless Steel | |||||||||

| 04 | 1/4 inch | ||||||||||||

| 06 | 3/8 inch | Outlet Gauge | Internal Surface Finish | ||||||||||

| 08 | 1/2 inch | None | No Gauge | None | EP – Electro Polished | ||||||||

| 0 | 0~30 psig | BA | BA | ||||||||||

| Maximum Inlet Pressure | 1 | 0~60 psig | |||||||||||

| 1 | 3000 psig / 206 bar | 2 | 0~100 psig | Trim Material | |||||||||

| 2 | 2500 psig / 172 bar | 3 | 0~160 psig | None | 316 SS | ||||||||

| 3 | 1000 psig / 69.0 bar | 4 | 0~200 psig | H | Hastelloy® | ||||||||

| 4 | 600 psig / 41.4 bar | ||||||||||||

| 5 | 300 psig / 20.6 bar | Seat Material | |||||||||||

| None | PCTFE | ||||||||||||

| Outlet Pressure Range | V | PI | |||||||||||

| A | 100 mm Hg absolute~30 psig / 100 mm Hg absolute~2.1 bar | ||||||||||||

| 0 | 1~30 psig / 0.1~2.1 bar | ||||||||||||

| 1 | 1~60 psig / 0.1~4.1 bar | ||||||||||||

| 2 | 1~100 psig / 0.1~6.9 bar | ||||||||||||

| 3 | 1~130 psig / 0.1~8.9 bar | ||||||||||||

| 4 | 1~150 psig / 0.1~10.3 bar | ||||||||||||

Specification

| Pressure Ratings | |||||

| Per criteria of ANSI/ASME B31.3 | Media Contact Materials | ||||

| Max. Inlet Pressure | 300, 600, 1000, 2500, 3000 psig (20.6, 41.4, 69.0, 172, 206 bar) | Body | 316L Stainless Steel | ||

| Diaphragm | Hastelloy® | ||||

| Outlet Pressure Range | 100 mm Hg absolute. ~ 30 psig (100 mm Hg absolute. ~ 2.1 bar) 30, 60, 100, 130, 150 psig (2.1, 4.1, 6.9, 8.9, 10.3 bar) | Seat | PCTFE (Optional PI) | ||

| Spring | 316 Stainless Steel or Inconel® | ||||

| Poppet, Retainer | 316 Stainless Steel or Hastelloy® | ||||

| Design Proof Pressure | 150% of maximum rated | ||||

| Internal Surface Finish | |||||

| Operating Temperature | Designator | Surface Finish(µm) | |||

| PCTFE Seat | -40~60℃ (-40℉~140℉) | Average | Maximum | ||

| PI Seat | -40~177℃ (-40℉~350℉) | BA | < 0.4 | < 1.6 | |

| EP | < 0.125 | < 0.4 | |||

| Flow Capacity | |||||

| Flow Capacity | 0.5 Cv 0.45 Cv (3000 psig, PCTFE Seat only) | ||||

| Helium Leak Test | |||||

| Inboard Leak Rate | 1x10-9 atm cc/sec He | ||||

Features

· The RCTS2 series, an ultra high purity tied diaphragm pressure reducing regulator, provides excellent stability of set pressure with accuracy and sensitivity

· Absolute pressure range option available

· Low internal volume

· Metal to metal diaphragm seals provide enhanced leak integrity

· The positive shutoff seal reduces creep

· Optimum performance and cleanliness at a great value

· All performed in Class 100 and Class 10 clean rooms.

Application

· UHP semiconductor manufacturing

· Regulation of specialty gases

· High flow purging systems

· 1/4” or 1/2“ Point of use

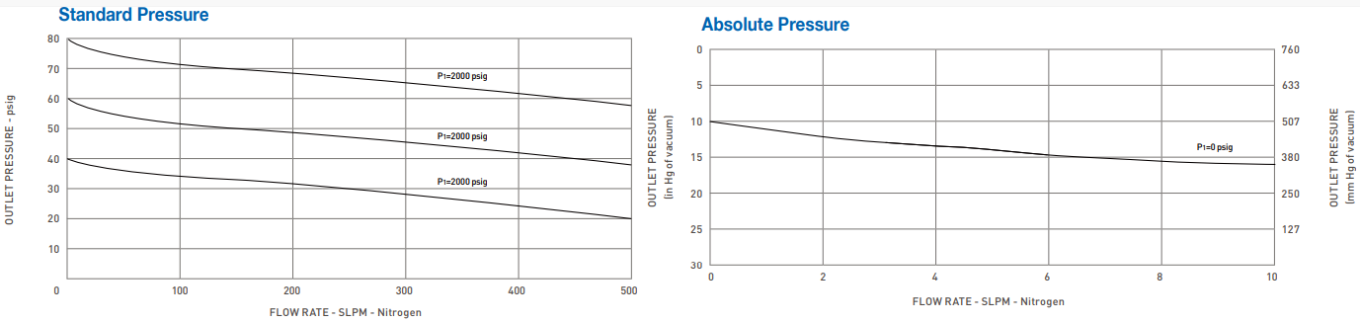

Flow Chart

top

top